The Mass Air Flow (MAF) sensor is crucial for modern vehicles' engine management, maintaining optimal fuel-air ratios and ensuring efficient performance, especially with high-performance exhaust systems. Inaccurate MAF sensor readings can lead to reduced efficiency, increased emissions, damage to engine and related components, and compatibility issues with modified parts. Regular calibration, clean intake components, proper sensor installation and wiring are essential for preserving accurate MAF sensor readings, enhancing fuel efficiency, and optimal engine performance.

In today’s digital era, ensuring precise vehicle tuning is paramount for optimal engine performance. Central to this process is the accurate functioning of the mass air flow (MAF) sensor. This critical component measures the volume of air entering the engine, directly impacting fuel injection and overall efficiency. Inaccurate MAF sensor readings can lead to poor tuning, reduced mileage, and even engine damage. This article delves into the crucial role of MAF sensors, explores the consequences of inaccurate readings, and offers strategies to ensure optimal accuracy for precise vehicle tuning.

- Understanding Mass Air Flow Sensor's Role in Engine Performance

- Impact of Inaccurate Readings on Vehicle Tuning and Efficiency

- Strategies to Ensure Optimal Sensor Accuracy for Precise Tuning

Understanding Mass Air Flow Sensor's Role in Engine Performance

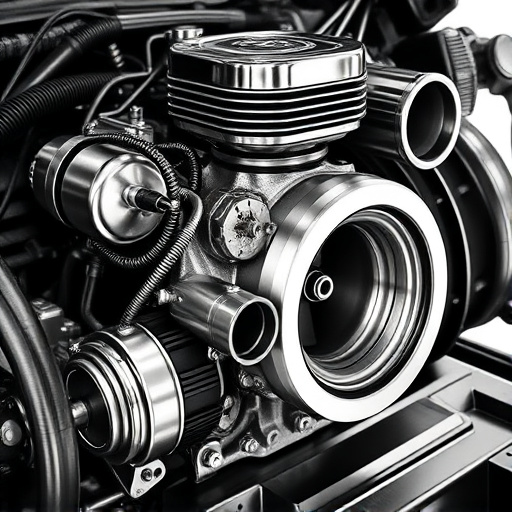

The Mass Air Flow (MAF) Sensor plays a pivotal role in modern vehicles’ engine management system. It acts as the eyes and ears of the engine, constantly monitoring and measuring the amount of air entering the combustion chamber. This real-time data is crucial for maintaining optimal fuel-air mixture ratios, ensuring efficient burning and maximizing engine performance. An accurate MAF sensor ensures that the engine receives the precise amount of fuel it needs, leading to improved vehicle performance and better control over emissions.

In vehicles with performance exhaust systems, which often modify the stock air intake and exhaust components for enhanced power output, a reliable MAF sensor becomes even more critical. These modifications can disrupt the standard air-fuel ratios calculated by the vehicle’s computer, potentially leading to poor engine performance or inefficient burning if the MAF sensor isn’t precise. Thus, ensuring the accuracy of the MAF sensor is essential for maintaining peak performance exhaust system efficiency and overall vehicle performance.

Impact of Inaccurate Readings on Vehicle Tuning and Efficiency

Inaccurate readings from a Mass Air Flow (MAF) sensor can significantly impact vehicle tuning and overall efficiency. The MAF sensor plays a crucial role in determining the amount of air entering the engine, which is essential for precise fuel injection and optimal combustion. When the sensor provides incorrect data, the engine control unit (ECU) adjusts fuel mixture ratios accordingly, leading to inefficient burning and reduced performance. This can manifest as poor fuel economy, increased emissions, and even potential damage to the engine due to incorrect fuel-air mixtures.

Moreover, inaccurate MAF sensor readings can cause issues with other components like exhaust tips, coilover kits, and brake rotors. For instance, if the ECU constantly adjusts for incorrect air intake, it might compensate by altering spark plug timing or fuel pressure, which in turn could affect the performance of exhaust systems or suspension components designed for optimal tuning under specific conditions. Thus, ensuring the accuracy of the MAF sensor is paramount for maintaining both vehicle efficiency and overall component harmony.

Strategies to Ensure Optimal Sensor Accuracy for Precise Tuning

To ensure optimal Mass Air Flow (MAF) sensor accuracy for precise tuning, several strategic approaches can be employed. Regular calibration is paramount; manufacturers recommend periodic checks to maintain sensor integrity. Calibration involves comparing the MAF sensor’s readings against known standards to adjust any deviations, ensuring accurate air-fuel ratios. Additionally, maintaining clean and undamaged intake components is vital as dirt or debris can impair airflow measurements, affecting engine performance.

Further enhancing accuracy includes regular cleaning of the sensor itself and nearby components, such as air filters and exhaust tips. Proper installation techniques are also critical; secure mounting and correct wiring prevent vibrations that could cause sensor drift. By combining these strategies, vehicle owners and mechanics can maximize MAF sensor accuracy, enabling optimal engine tuning for enhanced fuel efficiency and performance.

The accuracy of a mass air flow (MAF) sensor is paramount in achieving optimal vehicle tuning and fuel efficiency. Inaccurate readings can lead to poor engine performance, increased emissions, and reduced mileage. By understanding the sensor’s role, recognizing the effects of imprecise data, and employing strategies to ensure optimal accuracy, automakers and mechanics can harness the full potential of modern engines, contributing to both enhanced environmental sustainability and improved driving experiences.