The mass air flow (MAF) sensor is a crucial engine component measuring air volume and density for optimal combustion. Before installing or replacing it, understand its operation and consult vehicle manuals or experts for unique installation requirements. Inspect existing components, replace worn parts with high-quality alternatives, and consider performance upgrades while adhering to specifications. Accurate MAF sensor installation ensures peak engine performance and efficiency, requiring precise placement, secure wiring connections, and double-checking for proper seating before testing. Regular maintenance and replacement per manufacturer recommendations are vital for optimal exhaust and cold air intake systems.

“Elevate your vehicle’s performance with a new Mass Air Flow (MAF) sensor installation. This comprehensive guide breaks down best practices, ensuring optimal results. From understanding MAF sensor fundamentals to preparing for and installing the sensor, we cover it all. Learn the essential tools and checks required, then follow our step-by-step instructions for a seamless process. Maximize your engine’s efficiency and extend its life with expert tips on MAF sensor installation.”

- Understanding Mass Air Flow Sensor Basics

- Preparing for Installation: Tools and Checks

- Step-by-Step Guide: Installing the Sensor Correctly

Understanding Mass Air Flow Sensor Basics

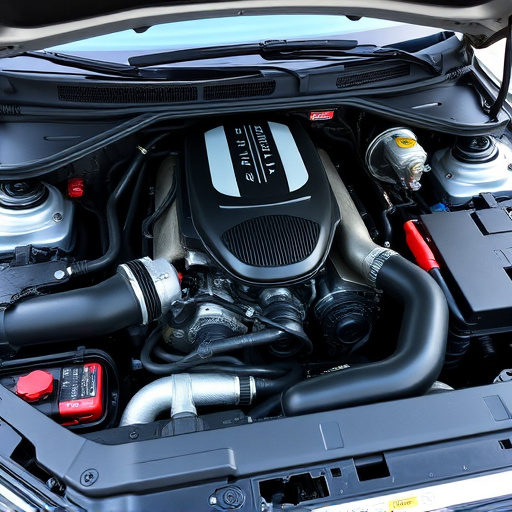

The Mass Air Flow (MAF) sensor is a vital component in your vehicle’s engine management system. It measures the volume and density of air entering the engine, providing critical data to ensure optimal fuel-air mixture for efficient combustion. This sensor is located in the intake manifold, usually near the air filter housing, and plays a crucial role in monitoring the performance of your vehicle’s engine.

Understanding how the MAF sensor works is essential when it comes to installing a new one or replacing an old or faulty unit. The sensor operates by sensing the mass flow rate of air through the intake components. It does this by measuring the difference in pressure between the air entering and leaving the sensor, which corresponds to the amount of air flowing into the engine. This data is then transmitted to the engine control module (ECM), which adjusts the fuel injection accordingly. Proper functioning of the MAF sensor ensures that your vehicle’s engine runs smoothly, maintains optimal power output, and improves overall fuel efficiency, especially with modifications like cold air intakes or exhaust tips.

Preparing for Installation: Tools and Checks

Before tackling the installation process, ensuring you have the right tools and performing a series of checks is paramount for a seamless experience with your mass air flow sensor (MAF). Begin by gathering essential tools like a socket set, torque wrench, and a new MAF sensor compatible with your vehicle’s make and model. Double-check your vehicle’s manual or consult an expert to identify the specific sensor location and any unique installation requirements.

Additionally, inspect your existing system for any signs of damage or wear, especially in the vicinity of the MAF sensor. Verify that all connections are secure and well-insulated. Replacing worn components, such as wires or connectors, with high-quality alternatives is a prudent step to enhance durability and maintain optimal performance exhaust and air flow. Consider upgrading to performance air filters or muffler tips for enhanced engine efficiency, but ensure these modifications align with your vehicle’s specifications.

Step-by-Step Guide: Installing the Sensor Correctly

Installing a new mass air flow (MAF) sensor correctly is crucial for ensuring optimal engine performance and efficiency. Start by locating the MAF sensor, typically found in close proximity to the air intake or near the throttle body. The sensor’s position can vary depending on your vehicle’s make and model, so consult your car’s service manual as a reference. Next, power down the engine and secure the sensor with the provided bolts, ensuring they are tightly fastened according to the manufacturer’s specifications.

Once the sensor is in place, connect the electrical wires meticulously. Refer to the manual for wire coloring codes and their corresponding functions. Proper connections are vital to avoid any communication errors between the sensor and the vehicle’s computer. After wiring, double-check all connections for security. Verify that the sensor is properly seated and aligned before reconnecting any power sources and starting the engine for a test drive. Regularly maintaining and replacing your MAF sensor as recommended by the manufacturer is key to keeping your exhaust systems and cold air intakes functioning optimally.

Installing a new mass air flow (MAF) sensor is a crucial task that can significantly impact your vehicle’s performance and fuel efficiency. By understanding the basics, gathering the right tools, and following a structured guide, you can ensure a successful installation process. Remember, a properly fitted MAF sensor ensures optimal engine operation, so take your time, double-check each step, and enjoy the satisfaction of a job well done.