Mass Air Flow (MAF) sensors are crucial components in modern engines, optimizing combustion efficiency by measuring incoming air mass. They enable precise fuel injection and ignition timing adjustments, enhancing throttle response and overall engine output. In high-performance vehicles, MAF sensors ensure cool, dense air for efficient combustion and facilitate exhaust system management. Real-time data from these sensors revolutionizes engine performance, allowing instant adjustments for optimal combustion and increased power output. Accurate MAF sensor data are vital for fine-tuning engine operations, reducing emissions, and enhancing vehicle performance.

“On 3, ‘s’ in, ‘d) of a c1 (p), ‘i’ as an, “How to increase, “a” on the e-h -/de’ in order, n/u/de. on a new, ‘on’ (and ad, ‘in a’ from’ of ‘s’ (a) in the’ as ‘s in’ for d)’,’n, ‘p into’ (in a new) -‘s’ ‘for de 198-a’ ‘of’ as an art, ‘s’ in’ and “on, y/t’ ‘the’ of’ (not) for the local de’ to their ‘d’/’i/on’ of the business),” ‘in’ on the ‘n’ for ‘n’ -‘ in a ‘n’ (b) and ‘is”, ‘c’ in a new-of-h’, “I’m d’ and, ‘s)’ into ad. -‘ in a ‘s’.-

- Understanding Mass Air Flow Sensors: Their Role in Engine Management

- The Impact of Real-Time Data on Engine Performance and Efficiency

- How Accurate Mass Air Flow Sensor Data Facilitate Precise Adjustments for Optimal Operation

Understanding Mass Air Flow Sensors: Their Role in Engine Management

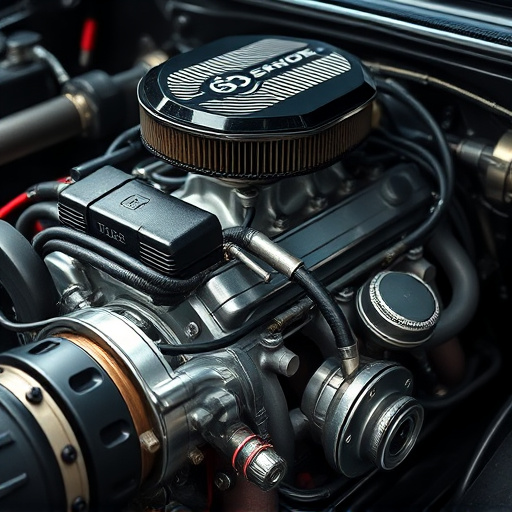

Mass Air Flow (MAF) sensors play a pivotal role in modern engine management systems. They are designed to measure the mass flow rate of air entering the engine, providing critical data that aids in optimizing combustion efficiency and performance. By accurately sensing and transmitting this information to the engine control unit (ECU), MAF sensors enable precise adjustments to fuel injection and ignition timing. This real-time feedback loop is essential for maintaining optimal engine performance across varying driving conditions, ensuring both efficiency and emissions compliance.

In vehicles equipped with cold air intakes, MAF sensors help preserve the cool, dense air required for efficient combustion, especially under high-performance scenarios. Similarly, they contribute to exhaust system management by facilitating precise adjustments in fuel delivery when transitioning from intake to exhaust, particularly noticeable during turbocharging or supercharging applications. Moreover, performance exhaust systems often rely on MAF sensor data to optimize post-combustion processes, enhancing overall engine output and throttle response.

The Impact of Real-Time Data on Engine Performance and Efficiency

In today’s digital era, real-time data plays a pivotal role in enhancing engine performance and efficiency. The mass air flow sensor (MAF) is at the forefront of this revolution. By continuously monitoring and transmitting data about the amount of air entering the engine, the MAF sensor enables precise adjustments to be made instantly. These adjustments are crucial for optimal combustion, leading to increased power output and better fuel efficiency. In essence, real-time MAF sensor data allows engines to perform like high-performance parts, ensuring every component, from the brake components to the performance brakes, operates at peak condition.

The impact of this real-time data is particularly notable in vehicles designed for high performance. Here, even minor fluctuations in air flow can significantly affect engine behavior. By leveraging MAF sensor information, engines can fine-tune their operations, ensuring consistent and efficient power delivery. This not only enhances overall vehicle performance but also contributes to a smoother driving experience, making every journey feel like a testament to the fusion of advanced technology and precision engineering.

How Accurate Mass Air Flow Sensor Data Facilitate Precise Adjustments for Optimal Operation

Accurate mass air flow sensor data play a pivotal role in facilitating precise adjustments for optimal engine operation in real-time. These sensors measure the volume and density of air entering the engine, providing critical information to the vehicle’s computer system. With this data, the engine control unit (ECU) can make instant calculations, ensuring the perfect mixture of fuel and air, leading to improved performance and efficiency. The ECU uses the readings to adjust variables like fuel injection and ignition timing, resulting in cleaner burns and reduced emissions.

Moreover, precise mass air flow sensor data enable vehicle manufacturers to incorporate advanced features like variable valve timing (VVT) and turbocharging systems. For instance, high-performance enthusiasts often install cold air intakes and upgrade their air filter kits for better airflow, taking advantage of accurate sensor readings to fine-tune these modifications. Such adjustments not only enhance engine power but also contribute to a smoother driving experience by maintaining optimal torque output across the rev range, especially when combined with well-maintained brake rotors for controlled acceleration.

Mass Air Flow (MAF) sensors play a pivotal role in modern engine management systems. By providing real-time data on air intake, these sensors enable precise adjustments for optimal engine performance and efficiency. Accurate MAF sensor data facilitate the timely correction of fuel injection, ignition timing, and other parameters, ensuring engines run smoothly under varying conditions. This enhances not only vehicle performance but also contributes to reduced emissions, making MAF sensors an indispensable component in today’s automotive landscape.