The Mass Air Flow (MAF) sensor is a critical component in modern engines, ensuring optimal air-fuel ratios for peak performance and efficiency. It prevents issues like engine knock by accurately measuring incoming air, especially crucial with modified cold air intakes or exhaust systems. Regular maintenance, cleaning, and wiring inspection, along with periodic calibration following vehicle modifications, are essential to keep the MAF sensor functioning optimally, thereby enhancing overall vehicle performance and prolonging component lifespan.

In the quest for smoother, more efficient engine performance, understanding ‘engine knock’ is key. This phenomenon can lead to serious damage if left unchecked. Thankfully, modern vehicles are equipped with a vital component: the mass air flow (MAF) sensor. This article delves into the critical role of the MAF sensor in preventing engine knock, exploring its functions, and providing tips on maintenance and calibration for optimal engine health.

- Understanding Engine Knock and its Impact

- The Role of Mass Air Flow Sensor in Prevention

- How to Maintain and Calibrate Your MAF Sensor for Optimal Performance

Understanding Engine Knock and its Impact

Engine knock, also known as detonation or pinging, is a common issue that can significantly impact vehicle performance. It occurs when the air-fuel mixture in an internal combustion engine ignites too early, leading to uncontrolled burning and potential damage to critical components like cylinder heads and valves. This phenomenon not only reduces engine efficiency but also produces unpleasant sounds and vibrations, affecting overall vehicle performance.

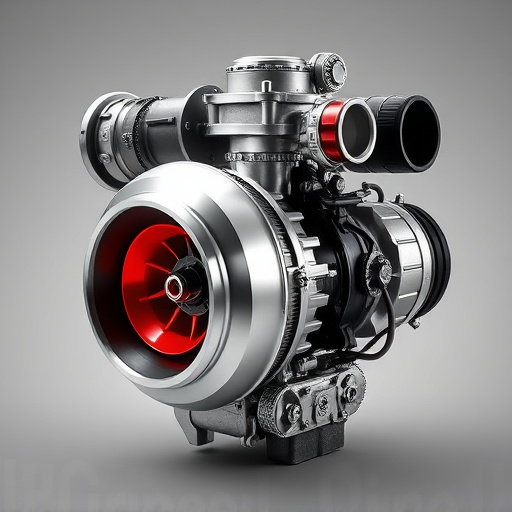

The mass air flow sensor (MAF) plays a pivotal role in preventing engine knock by accurately measuring the amount of air entering the engine. By providing real-time data to the engine control unit, the MAF sensor enables precise adjustments to the air-fuel mixture, ensuring optimal combustion. This, in turn, enhances vehicle performance and extends the lifespan of critical components, including brake rotors and performance brakes, which are less likely to suffer wear and tear from uncontrolled burning events.

The Role of Mass Air Flow Sensor in Prevention

The mass air flow sensor (MAF) plays a pivotal role in modern engines by accurately measuring the amount of air entering the combustion chamber. This data is crucial for maintaining an optimal air-fuel mixture, which directly impacts engine performance and efficiency. By ensuring the right balance of air and fuel, the MAF helps prevent issues like engine knock—a condition where pre-ignition occurs, leading to potential damage and reduced power output.

In vehicles equipped with cold air intakes or exhaust tips that modify airflow, the MAF sensor becomes even more critical. These modifications can alter the natural flow of air into the engine, potentially disrupting the delicate balance within the combustion process. The MAF sensor helps compensate for these changes by providing precise measurements, ensuring the engine continues to operate smoothly and efficiently, thus avoiding any unwanted consequences related to modified suspension components or exhaust systems.

How to Maintain and Calibrate Your MAF Sensor for Optimal Performance

Regular maintenance and calibration are crucial for keeping your mass air flow sensor (MAF) in optimal condition. To start, ensure that the sensor is clean and free from any debris or dirt buildup, as this can affect its readings and subsequently impact engine performance. A simple cleaning with compressed air can often do the trick. Next, check the sensor’s wiring connections for any signs of wear or damage. Tighten loose connections and replace any frayed wires to maintain reliable communication between the MAF sensor and your vehicle’s computer.

Additionally, periodic calibration is essential to ensure precise measurements. Many modern vehicles have self-calibration features that adjust based on driving conditions. However, if your car’s performance has degraded or you’ve recently installed a performance exhaust, brake rotors, or suspension kits, it might be necessary to manually calibrate the MAF sensor. This process typically involves driving at consistent speeds and allowing the vehicle’s computer to make adjustments for accurate readings. Following the manufacturer’s guidelines ensures that your MAF sensor remains finely tuned for optimal engine performance.

The mass air flow (MAF) sensor plays a pivotal role in preventing engine knock by accurately measuring the amount of air entering the engine. Regular maintenance and calibration of this vital component ensure optimal performance, thereby enhancing fuel efficiency and reducing the risk of costly engine damage. By understanding both the causes of engine knock and the crucial function of the MAF sensor, vehicle owners can take proactive steps to maintain their engines’ health and longevity.